Ready-to-fill packaging. Ready-to-move production. Ready when you are

Custom & Standardized Packaging from ALPLA – Ready to Fill Your Needs

Looking for a packaging manufacturer near you that can move fast, deliver reliably, and scale with you? ALPLA’s 17 high-capacity plants across the USA including locations in Jefferson City, Missouri, and Bowling Green, Kentucky are ready to support your production with custom and standardized bottles, closures, and containers.

Our high-capacity plants have room to take on additional production. We can help you develop new products in both custom-designed and standardized packaging formats providing the flexibility to meet your unique needs. Are you looking for a factory near you to diversify your supply chain, we’ve got the infrastructure, flexibility, and know-how to support your growth.

Why work with a plastic packaging manufacturer near you?

ALPLA has been innovating in plastic packaging for over 70 years and we have availability capacity. Choosing a plastic packaging factory near you means faster production, fewer logistics headaches, and more sustainable operations. By sourcing your PET and HDPE packaging locally, you can reduce transportation emissions. Here’s why it works:

What’s holding you back from localizing your packaging?

Why choose ALPLA for your packaging solutions?

At ALPLA, standard doesn’t mean generic. It means ready. We offer a wide range of solutions made with fully recyclable materials — PET, HDPE, rPET, PCR — all customizable through decoration, color, and closure choices

End-to-end solutions

We offer end-to-end collaboration — from concept development and technical design to production and logistics. And since we’re nearby, on-site meetings, line trials, and quality reviews can happen on your timeline.

Local Plants, Global Know-How

More than a manufacturer – Sustainability in Action

ALPLA doesn’t just bring production closer — we build sustainability into every step. Even with standard products, we bring you more than just a bottle. At our factories in Missouri and Kentucky we:

- Use energy-efficient machinery

- Run closed-loop water systems

- Recycle in-process material with low scrap rates

- Offer In-house rPET processing (recycled PET)

This means we can offer:

- Packaging made from up to 100% rPET and 100% PCR

- Lightweight designs that reduce material by up to 30%

- Fully recyclable monomaterials – no silicone or TPEs required

Local production also avoids unnecessary freight, helping you achieve your Scope 3 carbon reduction goals faster. We support both regional producers and national brands with scalable solutions. Whether you’re a mid-size co-packer or a fast moving consumer brand, our teams in Jefferson City and Bowling Green are ready to adapt to your needs. ALPLA’s regional footprint ensures your packaging is produced close to where it's needed — not on another continent.

Let’s calculate your CO₂ savings

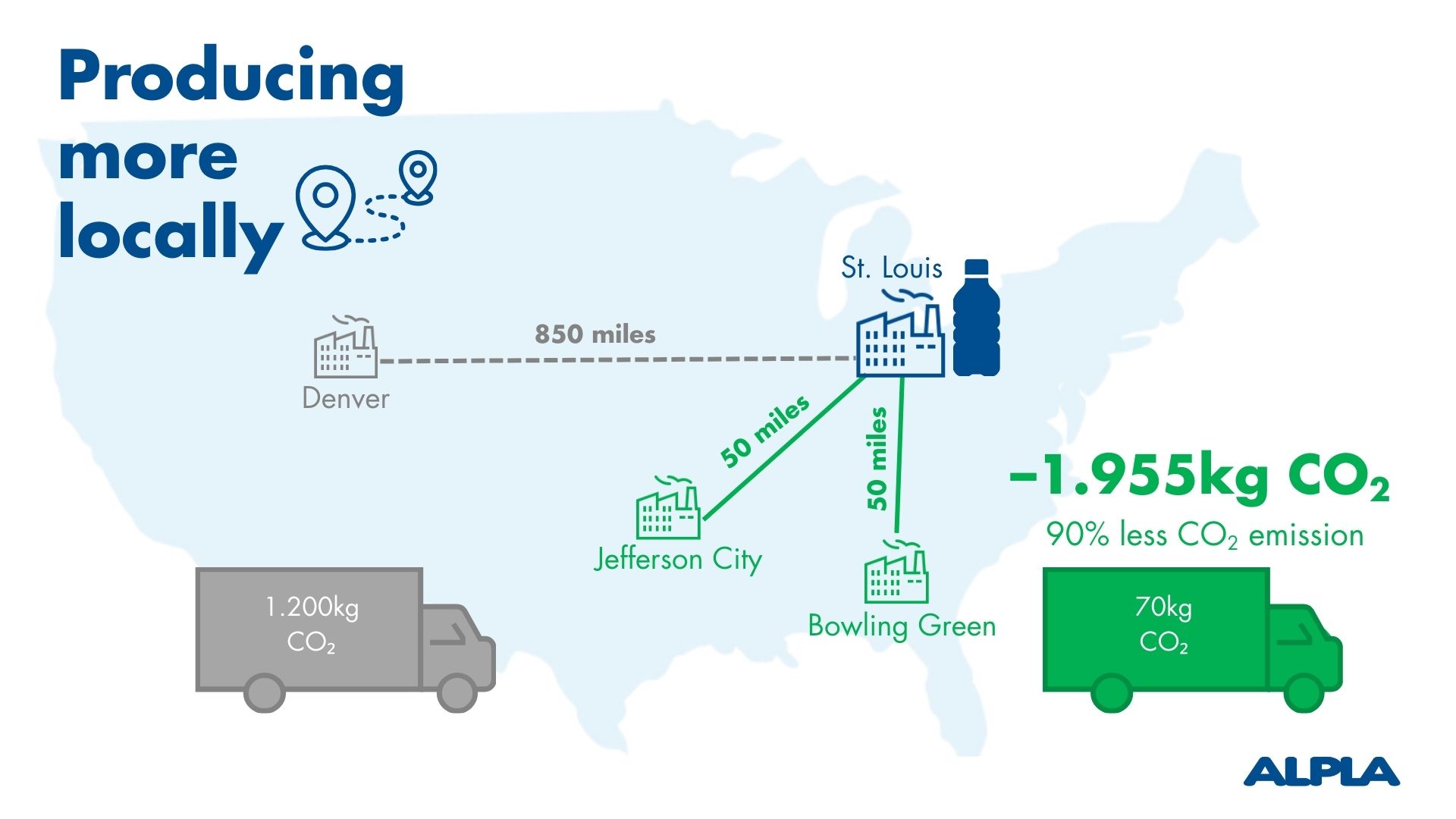

If your packaging currently travels 850 miles from Denver to St. Louis and you shift to a local ALPLA site just 50 miles from your filling location:

- That’s up to 85–90% less CO₂ emissions per truckload

- A typical 850-miles shipment emits ~1,200 kg CO₂

- The same load, shipped just 50 miles, emits only ~70 kg CO₂

And that’s before considering the additional savings from using recycled materials like rPET. Use our interactive tool to see how switching to local packaging production can reduce your carbon footprint. And also see the impact of choosing rPET over PET.

Over 150 companies across the United States already source their packaging from ALPLA.

Q&A

Absolutely. We offer PCR, rPET, and other sustainable materials that meet both regulatory and performance standards.

With local plants in Jefferson City and Bowling Green, we can react faster. With our in-house design support we can go from a concept straight into production.

No problem. We offer in-house design support and rapid prototyping to bring your idea to life quickly and affordably.

Yes. Our plants are equipped for flexible volumes—perfect for seasonal promotions or changing market demand.

Where are ALPLA’s American factories located?

Our Jefferson City, MO site is centrally positioned to serve the Midwest, while our Bowling Green, KY facility provides access to key logistics corridors and fast connections to the Southeast. Equipped with Extrusion Blow Molding (EBM), One-Step or Two-Step Stretch Blow Molding (SBM), and Injection Molding (IM) capabilities, we can meet diverse production needs.

Let’s Talk — We're filling capacity now

We’re actively looking for new partners to fill open production slots in Jefferson City and Bowling Green. If you're interested in high-quality packaging made locally — fast — we want to hear from you. Get in touch with our team today to get started. Or fill out our quick and easy webform to let us know what you need.

ALPLA INC.Base Plant

|

2662 Militia Drive 65101 Jefferson City Missouri |

United States of America |

North America |

ALPLA INC.Base Plant

|

1800 E. 94th Street Suite 300 64131 Kansas City Missouri |

United States of America |

North America |

ALPLA INC.Base Plant

|

215 Technology Way 42101 Bowling Green Kentucky |

United States of America |

North America |

ALPLA INC.Base Plant

|

2120 Spillman Drive 18015 Bethlehem Pennsylvania |

United States of America |

North America |