ISBM-Technology

ONE-STEP INJECTION STRETCH-BLOW MOULDING (PET & PP)

Our one-step injection stretch-blow moulding (ISBM) technology is perfect for manufacturing plastic bottles from recyclable materials like PET and PP, starting as small as 10 ml. These bottles are known for their high-quality, glass-like finish. ALPLA’s production facility in Kaiserslautern ensures seamless delivery to multiple countries, including Austria, Switzerland, Belgium, the Netherlands and France. The one-step ISBM process excels at creating complex shapes and structures to meet various product requirements in the plastic packaging manufacturing industry.

KEY BENEFITS

Plastic bottles with excellent surface quality

Our one-step ISBM process results in smooth, uniform plastic bottles, free from imperfections such as scratches and blemishes which are often found in the traditional two-step process. This ensures an appealing product appearance and enhances brand perception.

Customisable bottle shapes

PET and PP bottles manufactured using our ISBM one-step technology are a sustainable alternative to glass or metal packaging. We can create custom designs, from ampoules to large-volume wide-mouth containers, tailored to your specific manufacturing needs.

No support ring

The one-step blow-moulding production process eliminates the need for a support ring, allowing for even more customisation, especially in the neck area, while also enabling material savings.

Thick walls possible

The ISBM process allows for the production of thick-walled plastic bottles that closely resemble glass bottles, giving them a high-value look and feel.

WHY CHOOSE ALPLA FOR MANUFACTURING PLASTIC PACKAGING?

We provide flexible solutions for plastic manufacturing with our advanced machinery capable of quickly producing customised plastic packaging. Our global network ensures we have the expertise and resources to meet the evolving demands of the plastic packaging industry. ALPLA has deep roots in Germany and a strong understanding of market conditions and customer needs. To facilitate growth in other markets, we leverage the global presence of our sites, becoming a reliable international partner for plastic packaging manufacturers.

As a system supplier, we can also develop and produce customised closures for your packaging needs.

Sustainability is a core value at ALPLA, and we use recycled materials from our recycling plants. ALPLA is the largest PET recycler in Germany, ensuring that our customers have access to recycled materials and thus contribute to keeping plastics in the recycling loop.

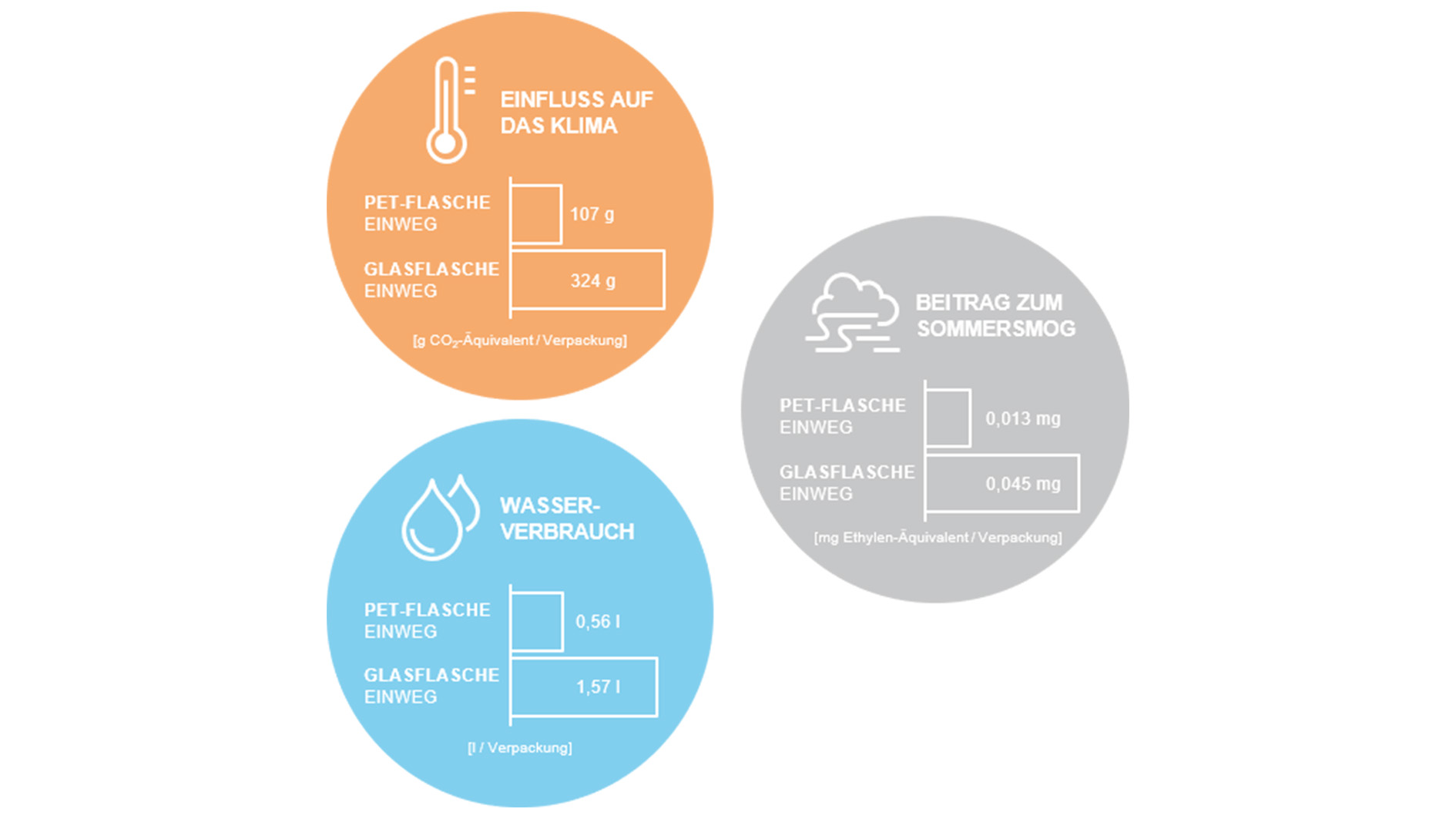

FOOTPRINT OF GLASS VERSUS PET BOTTLES

- Single-use PET generates 75% less CO2

- Single-use PET consumes only 1/3 of the water of a single-use glass bottle

- Single-use PET leads to 71% less summer smog than single-use glass bottles

- Multi-use PET generates 29% less CO2 than multi-use glass

Plastic can do much more than you think!

Its lightness and durability offer countless possible applications that make an important contribution to reducing our ecological footprint.

Read more about how plastic is helping to protect our climate.