Closures designed to open. Engineered to perform.

Tethered caps made to fit. Ready for every market.

ALPLA’s tethered closures are now a standardised solution to deliver reliable performance on the shelf, in the hand and across every shipment. From intuitive opening to precision fit, our caps are trusted by global brands for their durability, ease of use and reliable supply. The caps are tailored to meet the packaging demands of today’s largest consumer industries – beverages, food, and milk and dairy. Tethered caps are an EU-regulatory must-have and a packaging essential.

Reliable and efficient by design

Switching to tethered caps would not disrupt your production. ALPLA closures require minimal adjustments, helping you maintain high productivity and long-term cost efficiency.

Our integrated development teams – from R & D and Operations to Sales & Marketing – work with you throughout the project life cycle. With a closure portfolio that covers > 90% of the market volume for ISBT and Cetie needs, we provide robust, tested solutions aligned with ISBT and Cetie standards.

Compliant with EU Single-Use Plastics Directive

Since 2021, ALPLA’s tethered caps have supported compliance with the EU Single-Use Plastics Directive (EU 2019/904) – ensuring closures remain attached during opening and use. Our designs help you meet evolving legislation while maintaining consumer-friendly performance. Not an innovation, but an adaptation that has become an industry standard.

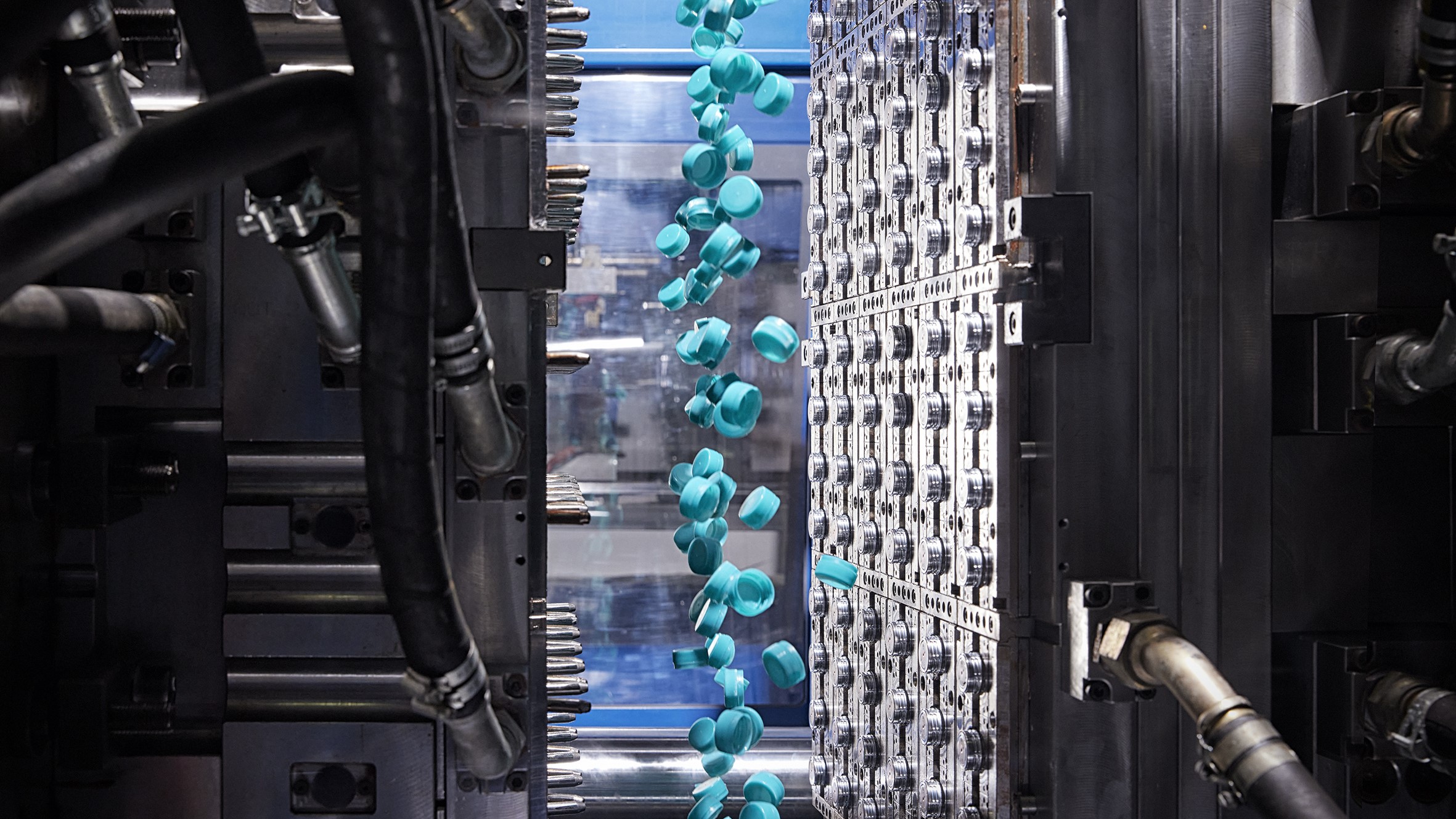

Precision manufacturing at global scale

Our closures are produced using state-of-the-art injection moulding and compression moulding technology, combined with automated downstream and finishing equipment. With manufacturing in all nine ALPLA regions and partnerships with trusted equipment suppliers worldwide, we ensure uniform quality at scale. With the closure market expanding by 5–6% annually, ALPLA is ready to scale with your growth – without compromising quality or consistency.

Injection moulding expertise behind every cap

Standardised product portfolio: tethered caps for every use case manufactured across multiple ALPLA sites, our closures are optimised for cold-fill and aseptic lines, with high-speed compatibility and regional production support. We offer a full range of tethered and standard plastic caps designed to serve a wide variety of markets:

- Non-carbonated beverages (NCB)

- Carbonated soft drinks (CSD)

- Juices, energy drinks, teas and syrups (JETS)

- Milk and dairy products

Product portfolio overview

Let’s create the best closure together

Whether you’re bottling soft drinks or milk and dairy and need a tethered closure, a standard screw cap or a custom-engineered fit, ALPLA brings the expertise, technology and global support to help you succeed.

From concept to production, we collaborate with you to create the best closure for your bottle, brand and line.

Business cases: collaborative circular design

See ALPLA and partners shaping sustainable packaging. These business cases highlight our leadership in plastic packaging solutions, forging a greener future together.